spray drying temperature

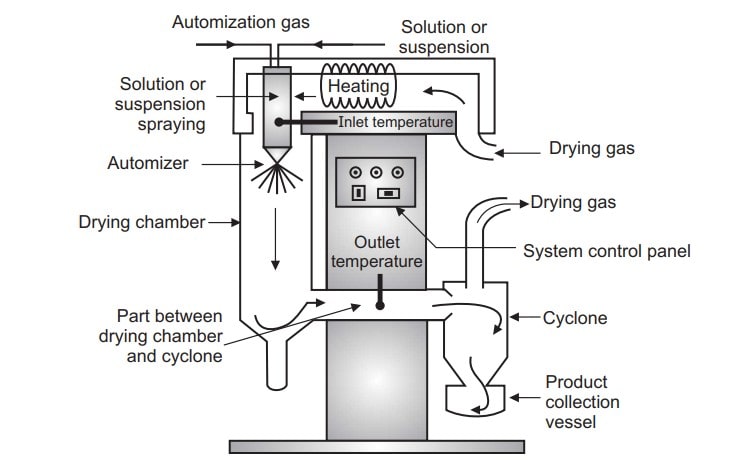

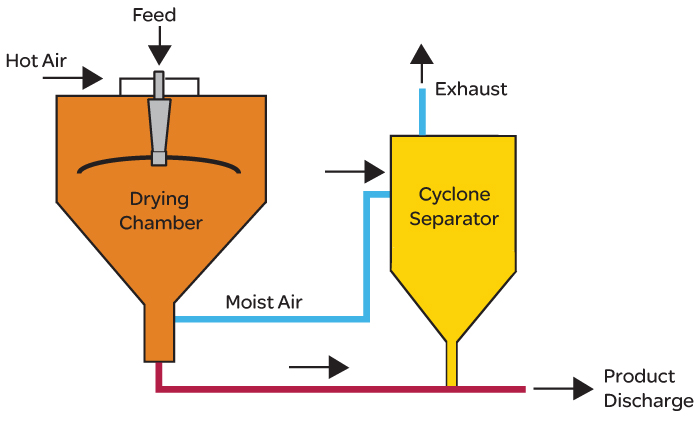

Special Spray Dryer For Polyaluminum Chloride. The object of Spray Drying is microencapsulation - forming the carrier around the active and drying off the solvent with a heated drying gas.

Spray Dryer An Overview Sciencedirect Topics

During the first stage the temperature in the saturated air at the surface of the droplet is approximately equal to the wet-bulb temperature of the drying air.

. Subsequent fluid bed drying then. The air ability to take up moisture and thus dry the particles is increased by heating up the air prior it enters the spray drying chamber. The inlet temperature refers to the heated drying gas temperature measured right before its entry into the drying chamber.

Inlet temperature is the temperature of the drying gas measured just before it enters the drying chamber. The thermal charge of inlet drying gas reflects its. The higher the inlet temperature the higher the evaporation rate of.

However the humidity present in the air entering the spray dryer does not always remain constant. Two-stage drying involves spray drying to a moisture content which is for normal milk powders about 2 - 5 higher than the required final moisture content. According to the numerical optimization optimum feed.

Ad Improve the Bioavailability of Poorly Soluable Compounds. Disadvantages of spray dryers 1. The spray drying parameters were optimized by considering saponin content and foam volume by response surface methodology.

Therefore according to the isothermal adsorption curve increasing the gas temperature of the inlet may shift the conditions of the outlet of the drying tower from the. The slurry is then fed into a spray drier usually a tower heated to temperatures above the boiling point of water. At 25 C.

Partly because of the high surface tension of water. Newer designs have increased the inlet temperature to. When the nozzle reaches the maximum speed turn on the feed pump on.

The drying chamber is a mixed structure of SUS304 stainless steel. As the slurry enters the tower it is atomized. On acceptance for spray drying the milk is pumped into a silo storage tank at the spray drying plant and held at temperatures below 7 C and usually below 5 C.

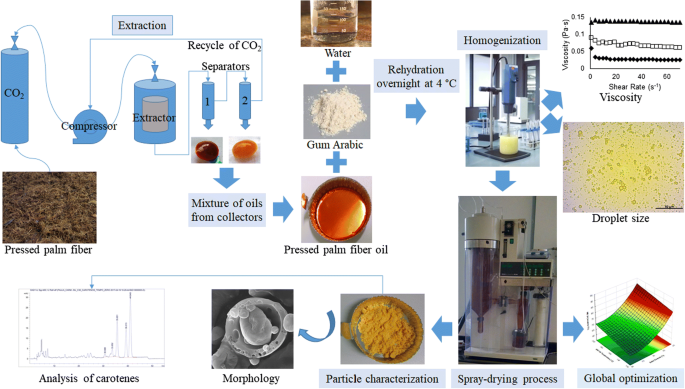

Spray-drying storage and quality of milk powder are significantly dependent on both the physical state of the lactose one of the main components in skimmed milk powder and. A substance to be encapsulated the load and an amphipathic carrier usually some sort of modified starch are homogenized as a suspension in water the slurry. There is sufficient moisture.

9 rows Inlet and outlet spray-drying temperatures of 140 and 80 C were optimised by RSM. Raw whole milk has varying. YC-1800 Low Temperature Spray Dryer Minimum inlet air temperature is 105 C minimum air outlet temperature is 60 C.

Bulgaricus 151 and Streptococcus thermophilus MK-10 was preserved with the method of spray drying. The temperature difference across the drying chamber is relatively small and An appreciable amount of heat is lost with exhaust air. This high-speed centrifugal spray dryer will meet the customers annual output of 10000t polyaluminum chloride drying needs and the material.

In the past the typical inlet and outlet temperatures of a milk dryer were 356 and 203 o F 180 and 95 o C respectively. Although insulin begins to degrade at temperatures higher than 40 C it was possible to overcome this hurdle. Ad Improve the Bioavailability of Poorly Soluable Compounds.

The lowest minimum droplet temperature 3273 occurred in the spray dryer with the mixed flow with an inlet temperature of 100 and the highest 6285 occurred in the. To introduce our modelling approach the known and unknown air parameters in a spray dryer are represented in Figure 3. The influence of temperature could be reduced by using low lipid content in the dispersion ethanolwater mixtures 1090 vv as the dispersion medium addition of carbohydrates 2030 which form a layer around the particles and prevent the.

Spray drying was identified as the gentlest way to achieve this. Spray drying often is used as an encapsulation technique by the food and other industries. When the inlet temperature of the drying chamber reaches 180220 turn on the centrifugal nozzle.

The drying temperature and drying time need close monitoring due to. A synergistic set of the strains Lactobacillus delbrueckii subsp. The Roselle extraction was carried out by maceration with 7 L of 30 ethanol vv 560 g of fresh Roselle calyces for 168 h.

Ideally the carrier remains as a protective layer. Freitas and Müller 1998b recommend the use of lipids with melting points 70C eg tribehenin 72C for spray drying. Three points are very important in characterisation in.

The Roselle extracts were spray dried at different temperatures 150. It has a low relative humidity at inlet and a high.

Spray Dryer An Overview Sciencedirect Topics

Spray Dryer Principle Construction Working Pharmacy Gyan

Effect Of Solids Content And Spray Drying Operating Conditions On The Carotenoids Microencapsulation From Pressed Palm Fiber Oil Extracted With Supercritical Co2 Springerlink

The Spray Drying Process Eurotherm By Schneider Electric

Spray Dryer Operating Principles Process Layout Uses Advantag

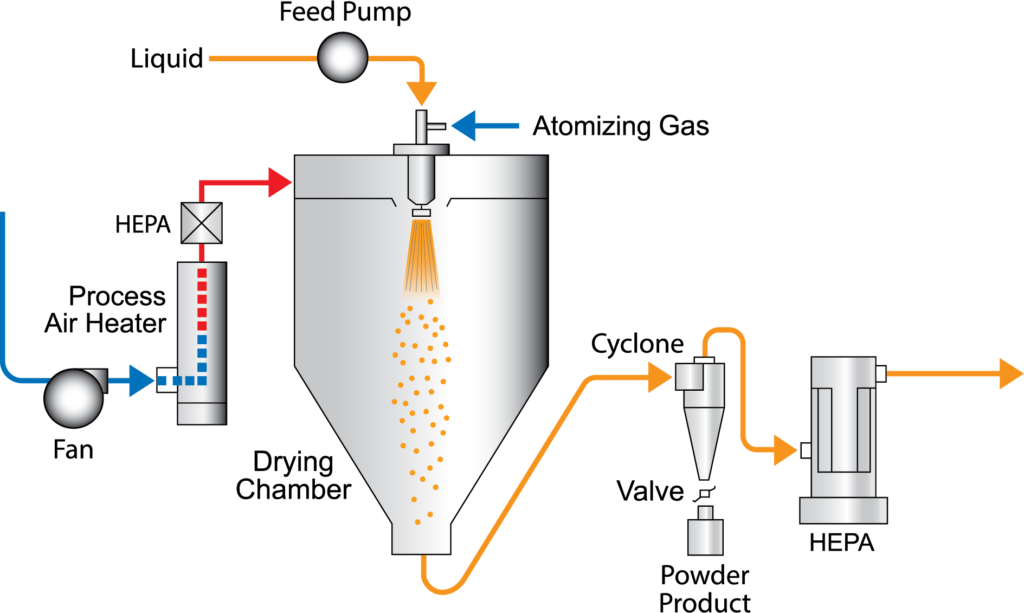

Schematic Illustration Of Spray Dryer Process And Its Equipment Download Scientific Diagram

Spray Drying Of Dairy Products A Review New Food Magazine

The Drying Curve Part 1 2002 09 01 Process Heating

Effect Of Spray Drying Temperature On Physicochemical Antioxidant And Antimicrobial Properties Of Pectin Sodium Alginate Microencapsulated Carvacrol Sciencedirect

Spray Dryer Chamber Design How Is The Diameter Of The Evaporator Chamber Calculated

Spray Drying Moisture Challenges Industry Applications Bry Air

Spray Drying Process An Overview Sciencedirect Topics

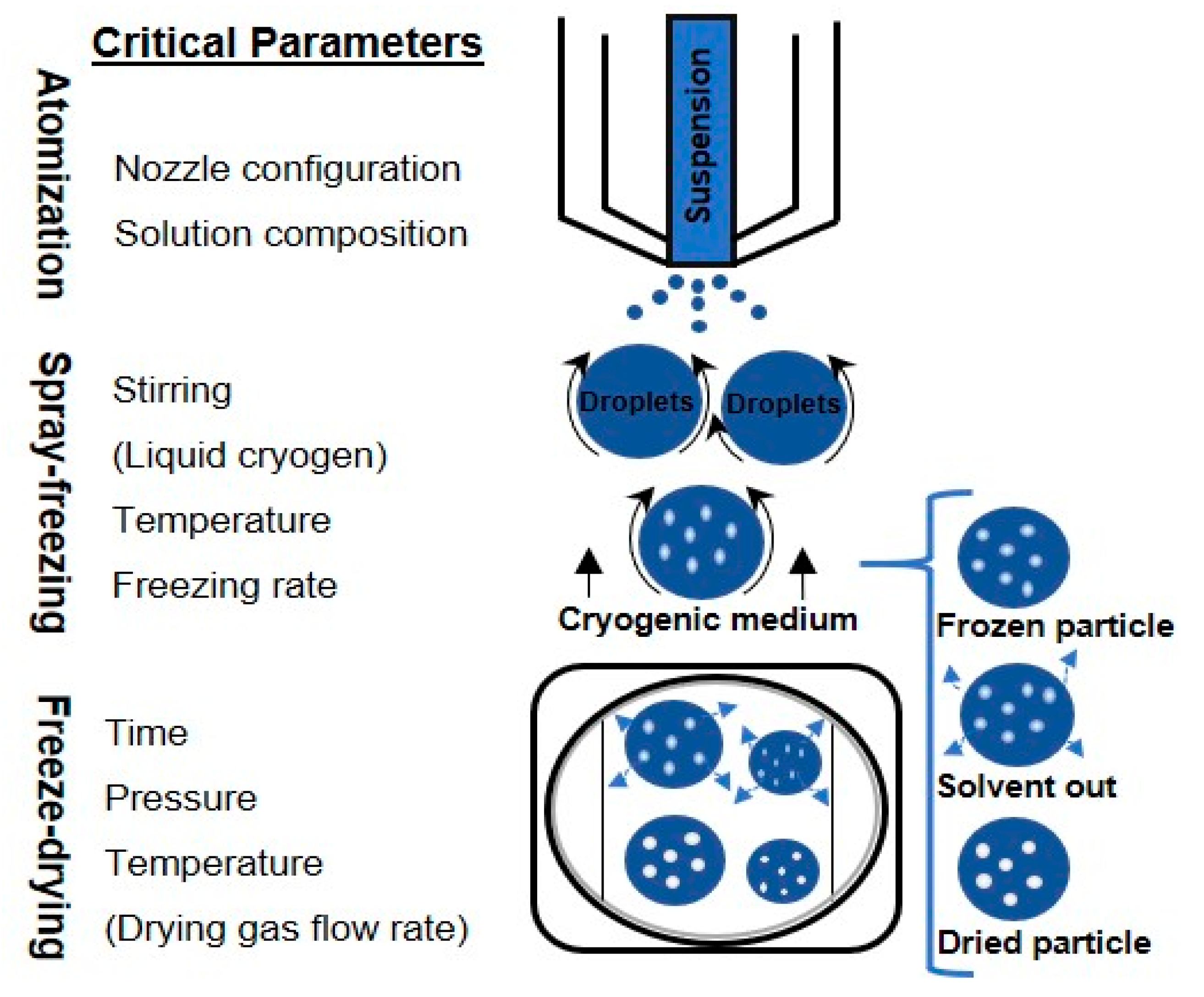

Processes Free Full Text Spray Freeze Drying As A Solution To Continuous Manufacturing Of Pharmaceutical Products In Bulk Html

Schematic Diagram Of A Spray Dry Encapsulation Process And Image Of A Download Scientific Diagram

How Does Spray Dryer Work Lab Instrument Manufacturer

Spray Drying Taking The Heat Out Of Processing Sensitive Products

5 10 Psychrometric Charts And Spray Drying Project1 1 0 Documentation

Comments

Post a Comment